ARGOTEC REPARACION R4 RAPIDO

Rapid-setting structural concrete repair mortar

Product variations:

ARGOTEC REPARACIÓN R4 RÁPIDO is a thixotropic polymer modified mortar (PCC), single-component, fast setting and non-shrink, for structural repair of concrete elements, formulated based on a mixture of hydraulic binders, selected aggregates, polymers, corrosion inhibitors and fibres that provide excellent adhesion and mechanical properties.

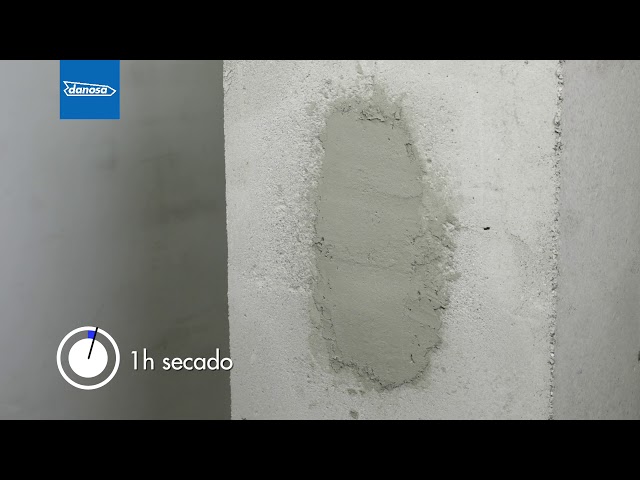

Installation video

Scope

- Installation of gutters, manholes and wells.

- Conservation and restoration of coats. Principle 7. Methods 7.1 and 7.2.

- Repair of prefabricated elements.

- Repair and regeneration of structural elements.

- Structural concrete reinforcement works. Principle 4. Method 4.4.

- Concrete repair work. Principle 3. Methods 3.1 and 3.3.

- Repair work on edges, cornices, balcony edges and roofs.

Advantages & Benefits

- Outstanding Adhesion

- Excellent workability.

- Free of chlorides.

- Made of sulphur-resistant cement.

- Quick commissioning.

- No retraction.

- Thixotropic.

- Rapid development of resistance.

Descriptive Memory

The repair of concrete elements will be carried out with ARGOTEC REPARACIÓN R4 RÁPIDO mortar, from the company Argos derived from cement, class R4 according to the UNE EN 1504-3 standard, in accordance with principle 3 (methods 3.1 and 3.3), principle 4 (method 4.4.) or principle 7 (methods 7.1. and 7.2.). The fixing substrate shall be sound, clean, free of friable parts, fully hardened and have completed its time of dimensional variation. The construction joints shall be respected.

Support

- Precast concrete elements.

- Concrete structures.

Substrate preparation

- In any case, the specific requirements of EN 1504-10 must be taken into account.

- Metal elements, such as reinforcement, must be free of rust, dust, mortar residues or other materials that may impede adhesion or contribute to corrosion.

- Absorbent substrates must be wetted to saturation without puddling.

- The substrates must be clean and sound, free of grease, paint or other substances that would prevent proper adhesion.

- Very smooth substrates shall be mechanically treated to ensure proper adhesion of the mortar.

- A suitable adhesion primer shall be used on low-porosity surfaces.

Instruction for Use

Surface Preparation / Priming Careful surface preparation is essential for optimum finish and durability. The surface needs to be clean, dry and sound, free of any contamination, which may harmfully affect the adhesion of the coating. New concrete structures need to dry for at least 28 days. Old coatings, dirt, fats, oils, organic substances and dust need to be removed by a grinding machine. Possible surface irregularities need to be smoothened. Any loose surface pieces and grinding dust need to be thoroughly removed. Do not wash surface with water! Do not apply the REVESTIDAN FINISH when the ambient temperature is below +5ºC during the application and 4 hours afterwards, on surfaces with Temperature below +5ºC, on frozen surfaces, during rain or mist, and on surfaces with ascending humidity. Low temperatures retard cure while high temperature speed up curing. REVESTIDAN FINISH is slippery when wet. In order to avoid slipperiness during wet days, sprinkle suitable aggregates onto the still wet coating to create an anti-slip surface. Waterproofing membranerStir REVESTIDAN FINISH slowly and well with wooden staff before using. Do not use a mechanical drill. Apply REVESTIDAN FINISH onto the prepared and/or primed surface by roller or brush (in details use a roller 10 cm width), until all surface is covered. If necessary apply a second layer.

Warning

- Do not apply when there is a risk of frost, rain, strong wind or direct sunlight.

- Do not apply below 5°C or above 30°C.

- Do not apply on plaster supports.

- Do not apply to plastic, wood, rubber, etc. surfaces.

- Protect the cool surface from direct sun, rain and especially draughts.

Handling, storage and preservation

- It is packaged in 25 kg multi-leaf paper bags with damp-proof sheets that allow it to be stored for 12 months in its original sealed packaging, safe from dampness.

Cleaning of Work Tools

Tools are easily cleaned with water before the adhesive has hardened.

Safety and hygiene

- Disposal of the product and its packaging must be carried out in accordance with current legislation and is the responsibility of the end consumer of the product.

- For any information concerning safety issues in the use, handling, storage or disposal of chemical residues, users should refer to the most recent version of the MSDS.

Notice

- The information contained in this document and any other advice provided, are given in good faith, based on DANOSA's current knowledge and experience when products are properly stored, handled and applied, in normal situations and in accordance with the recommendations of DANOSA. The information applies only to the application (s) and the product (s) to which reference is expressly made. In case of changes in the parameters of the application, or in case of a different application, consult the DANOSA Technical Service before using the DANOSA products. The information contained herein does not exonerate the responsibility of the building agents to test the products for the application and intended use, as well as their correct application in accordance with current legal regulations. The product images used in our communications are indicative and may differ slightly in color and aesthetic appearance in relation to the final product.Orders are accepted in accordance with the terms of our current General Sales Conditions.DANOSA reserves the right to modify, without prior notice, the data reflected in this documentation.Website: www.danosa.com E-mail: info@danosa.com Telephone: +34 949 88 82 10

Presentation

- Appearance: Powder

- Colour: Grey

- Weight (kg): 25

- Yield (kg/m²): 18 kg/m² y cm de espesor

- Performance in mm thickness (kg/m²): 1,8

- Product code: 350145

Technical Data

| Concept | Value | Standard |

|---|---|---|

| Mass per unit area (nominal) (kg/m²) | 25 | - |

| Capillary Absorption (kg/m²h0.5) | W2 | - |

| Classification according to UNE EN 1504-3 | R Rápido (PCC) | - |

| Thermal compatibility. Part I. (N/mm²) | 2 | - |

| Thermal conductivity declared (W/mK) | 1 | - |

| Chloride ion content (%) | 0.05 | - |

| Bulk density (kg/L)v ~ Value | 1,50 ± 0,16 | - |

| Fresh mass density (kg/L) ~ Value | 1,80 ± 0,16 | - |

| Maximum thickness (mm) | 30 | - |

| Minimum thickness (mm) | 10 | - |

| Water vapour permeability (m) | Clase I | - |

| Reaction to fire | A1 | - |

| Compacting resistence 1 hour (N/mm²) | ≥ 5 | - |

| Compacting resistence 24 hours (N/mm²) | ≥ 15 | - |

| Compacting resistence 28 days (N/mm²) | ≥ 45 | - |

| Compacting resistence 7 days (N/mm²) | ≥ 30 | - |

| Flexural strength after 28 days (N/mm²) | ≥ 2 | - |

| Resistance to carbonation | Pasa | - |

| Retraction at 28 days (mm/m) | ≤ 0,1 | - |

| Hazardous substances | Ver HS | - |

| Application time (min) | 15 | - |

Addtitional Technical Data

| Concept | Value | Standard |

|---|---|---|

| CO2 permeability | Clase III | - |