Sustainability

Sustainability is not an objective. It is an attitude in itself.

At DANOSA, we want to promote a new way of understanding sustainable construction, relating, creating synergies, and combining experiences to move forward together.

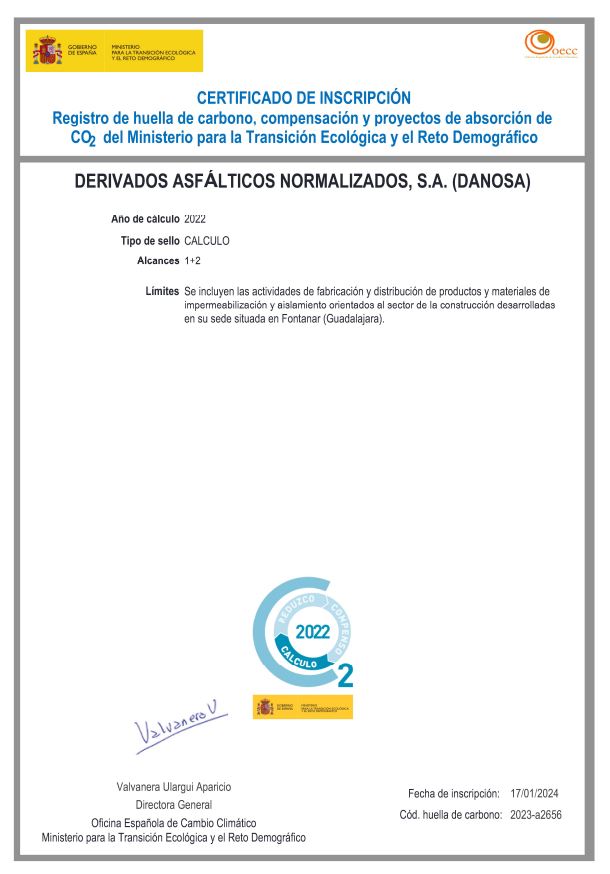

Several years ago, we began developing solutions to improve energy efficiency and health in buildings while reducing CO2 emissions into the atmosphere and thus helping to curb climate change.

We have since proposed to go one step further, leave the linear economy behind and start developing a model based on the circular economy: creating recyclable products, turning waste into valuable resources, and optimising our production process to the maximum to achieve the minimum possible impact on the environment.

The implementation of new technologies in the production process and our continuous research and development work have allowed us to reach unprecedented levels of product quality, putting the customer and nature at the center of our activity.

The depletion of the planet’s material resources is an undeniable fact, making us question our current economic model and value more sustainable alternatives that respect the environment.

The circular economy is a European initiative within the framework of the European 2020 strategy that aims to reduce the entry of virgin raw material and the generation of waste and residues, closing the economic and ecological flows of resources. The linear system of our economy has reached its limits and the depletion of natural resources and fossil fuels is beginning to be seen. The circular economy proposes a new model that optimises the flows of materials, energy, and waste. Its objective is the efficiency of the use of resources.

36%

of the EU’s CO2 emissions are generated by buildings.

The circular economy in Danosa, from words to deeds

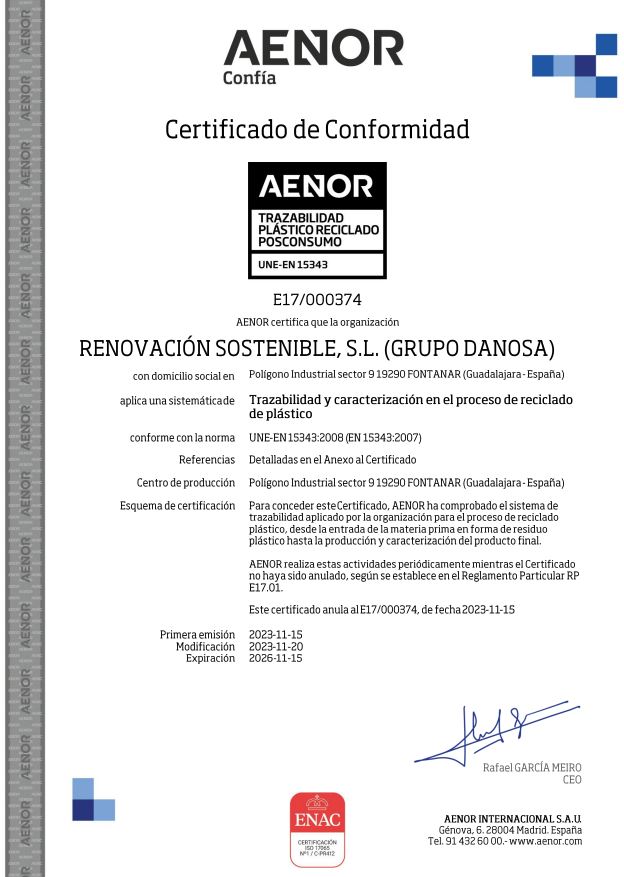

In 2012 DANOSA created RENOVACION SOSTENIBLE (aka SUSTAINABLE RENEWAL), the group company whose main activity is the management and recovery of waste for its incorporation into the manufacture of DANOSA products.

In 2016 we started commercialising recovered waste to other companies both in Spain and in the rest of Europe.

18.000.000

We use the equivalent of 18 million eps fish boxes to manufacture our XPS thermal insulation

At the end of its useful life, plastic is not a waste. It is a resource.

8.000 Tn

of recycled materials, in our production processes, we have consumed during 2018.

HDPE

1.700t* high-density polyethylene

EPS

4.530t* expanded polystyrene

PP

1.500t* polypropylene

LDPE

1.700t* high-density polyethylene

Innovation and development

For Danosa, sustainability is the decisive parameter when selecting an Innovation and Development project.

Danosa has a team of specialised researchers who lead the R&D department. As a result, significant investments have been made in technology and equipment in recent years.

We have the ability and knowledge to develop our own formulations to improve the performance of our products, certify the composition of raw materials and control the traceability of the entire manufacturing process.

Thanks to this research effort, today, a good part of the raw materials used by Danosa in the elaboration of its range of products comes from recycled materials. Not only do we grant a second life to waste materials, but we also value them as valuable resources without reducing the technical performance of the final product and validating greater durability.

+40%

of all the materials we use to make our products are recycled.

A challenge for the entire sector

Starring architects, developers, manufacturers, builders, installers, investors and distributors.