THERMOBOND

A quick, moisture-curing polyurethane adhesive.

Product variations:

DANOSA THERMOBOND is a solvent-free, non-flammable and low odour liquid insulation adhesive with high-foaming and fast-curing properties. THERMOBOND adhesive is suitable to bond a wide range of insulation boards to foil and sand-faced bitumen air and vapour control layers (AVCL’s) or to bond multiple insulation layers together. This product code is delivered for pour and roll application.

Support

- Tissue faced PIR insulation boards.

- Sand-faced and foil-faced bitumen AVCL’s.

- Mineral wool insulation.

- Vacuum insulation panels.

- Existing reinforced bitumen felt and asphalt surfaces.

- The substrate must be solid, with a suitable surface condition prior to work commencing and able to resist all dead and imposed loadings. Of the two surfaces to be bonded, at least one surface must be porous to effect a full bond, e.g. tissuefaced PIR insulation to a sand or foil-faced AVCL would be suitable. However, a foil-faced PIR to the same AVCL would not. Adhesion tests should be carried out prior to use. THERMOBOND should only be used for the substrates listed. For any other applications, please contact DANOSA UK technical department at uktechnical@danosa.com.

Instruction for Use

The instructions for application below are for guidance only. Please always refer to any project-specific DANOSA UK recommendations. Adhesion tests should be carried out ideally a minimum of 48-hours prior to general installation works commencing.

Wind uplift performance:

Roof systems constructed with THERMOBOND were tested at BRE premises by the supplier and achieved a wind uplift resistance of between 5000 Pa and 5500 Pa.

- Ensure that all surfaces to be bonded are clean, dry and free from contamination.

- Ensure that the substrate surface is relatively flat, with no significant variations in level to prevent air gaps under the insulation board and to ensure a maximum of surface contact and that there are no fixings protruding from the deck surface. The substrate surface must be solid and capable of transferring all loadings to the structure.

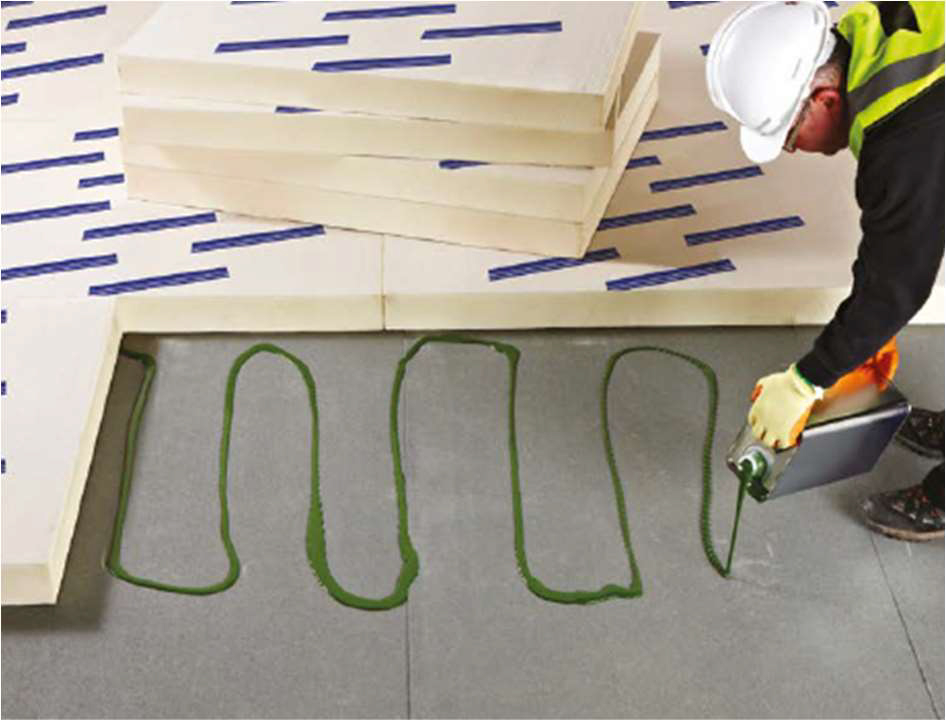

- Apply THERMOBOND solvent-free insulation adhesive directly on to the substrate (deck/ AVCL/insulation board) in beads 10mm

- 20mm wide, at 200mm

- 300mm centres.

- Immediately place the insulation board directly on to the adhesive.

- Apply pressure to the insulation board to ensure full contact with the adhesive.

- Allow to cure.

Wind uplift performance:

Roof systems constructed with THERMOBOND were tested at BRE premises by the supplier and achieved a wind uplift resistance of between 5000 Pa and 5500 Pa.

Indications and Important Recommendations

- Carbon Dioxide will be given off if water enters the adhesive container, which can cause pressurisation.

Warning

- Disposal of used tins should be classified as packaging containing residues of/ or contaminated by hazardous substances using waste code EWC 15 01 10. For further information, please contact DANOSA UK technical department, at uktechnical@danosa.com.

- Please see product safety datasheet for further information.

Handling, storage and preservation

- This product should be stored unopened in dry conditions, out of direct sunlight, at an ambient temperature of 5°C to 25°C. This will ensure that the stated shelf-life is achieved. Once opened, the products shelf-life will reduce.

- NB. Each THERMOBOND container contains a layer of nitrogen to prolong shelf life. Once opened, this layer will disappear, and the adhesive shelf life will be reduced.

Notice

- The information contained in this document and any other advice provided, are given in good faith, based on DANOSA's current knowledge and experience when products are properly stored, handled and applied, in normal situations and in accordance with the recommendations of DANOSA. The information applies only to the application (s) and the product (s) to which reference is expressly made. In case of changes in the parameters of the application, or in case of a different application, consult the DANOSA Technical Service before using the DANOSA products. The information contained herein does not exonerate the responsibility of the building agents to test the products for the application and intended use, as well as their correct application in accordance with current legal regulations. The product images used in our communications are indicative and may differ slightly in color and aesthetic appearance in relation to the final product.Orders are accepted in accordance with the terms of our current General Sales Conditions.DANOSA reserves the right to modify, without prior notice, the data reflected in this documentation.Website: www.danosa.com E-mail: info@danosa.com Telephone: +34 949 88 82 10

Presentation

- Volume (L): 6

- Coverage (m²): 30 - 60 per 6 L TIN (6.5 kg)

- Colour: Brown

- Product code: 320107

Technical Data

| Concept | Value | Standard |

|---|---|---|

| Base | Polyurethane | - |

| Temperature resistance (ºC) | -40 / 140 | - |

| Application temperature (ºC) | 5 / 30 | - |

| Storage temperature (ºC) | 5 / 25 | - |

| Open time (min) | 5 (20ºC) | - |

| Cure time at 20 ºC (min) | 30 | - |

| Viscosity (cps) | 4000 | - |

Addtitional Technical Data

| Concept | Value | Standard |

|---|---|---|

| Solids content (%) | 100 | - |

| Storage time (months) | 12 | - |