Cold and hot liquid roofing are two different methods of applying liquid coatings to a roof surface in order to achieve its complete waterproofing. While both options have their own unique advantages and disadvantages, the choice between them often depends on the specific needs and requirements of the project.

Cold-applied Liquid Waterproofing:

Pros:

- Ease of Installation: Cold liquid roofing shines in its straightforward installation process. It eliminates the need for heat or flame, significantly reducing the risk of fire, damage, or harm to roofing personnel.

- Versatility: This method is adaptable, suitable for various surfaces including concrete, metal, timber, and bituminous felt.

- Customisation: Cold liquid roofing offers a wide array of colours and finishes, making it a versatile choice for diverse projects.

Cons:

- Durability Concerns: Cold liquid roofing is not as durable as Hot Melt. It may be susceptible to cracks and splits over time, potentially leading to leaks and requiring more frequent maintenance.

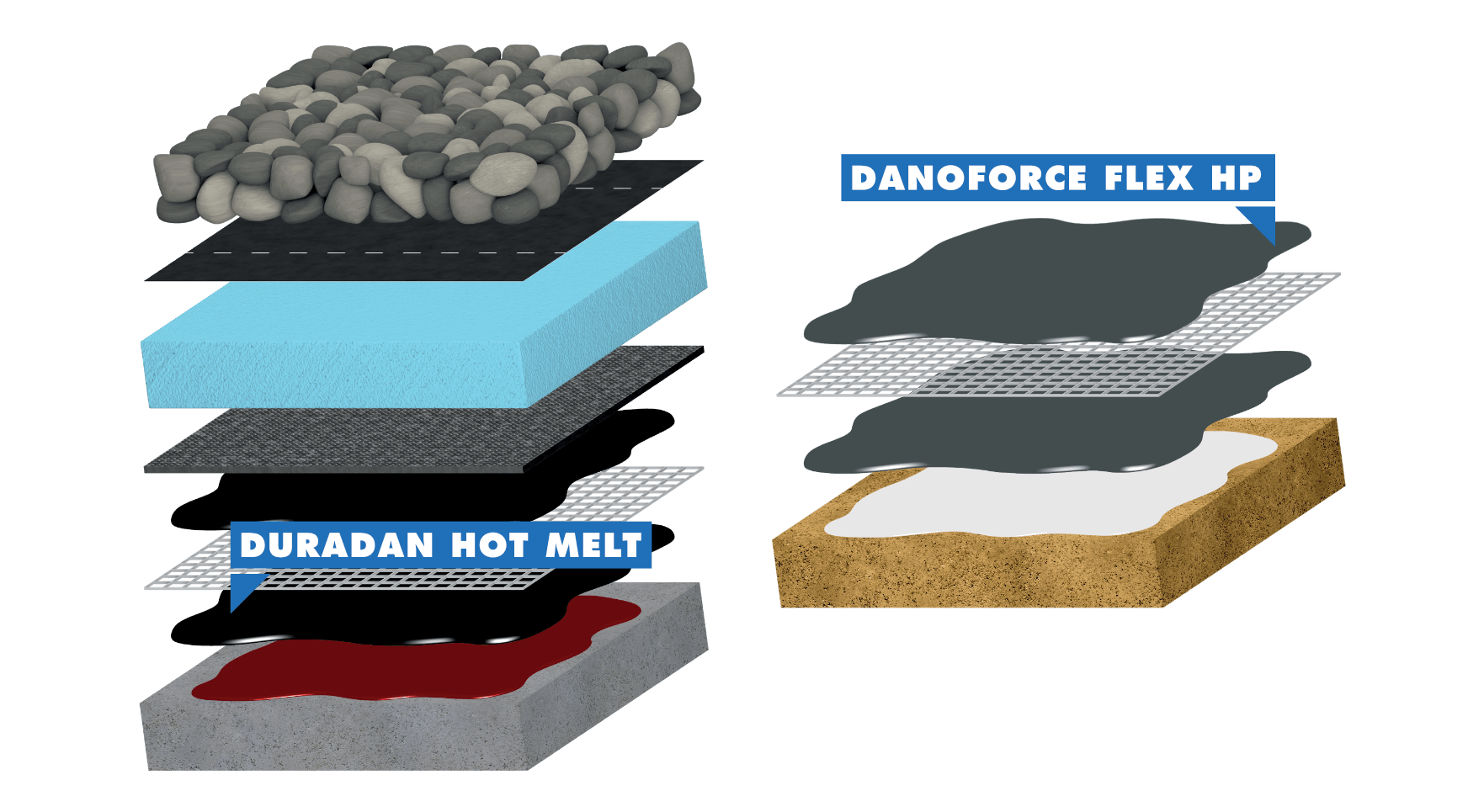

Hot Melt Structural Waterproofing:

Pros:

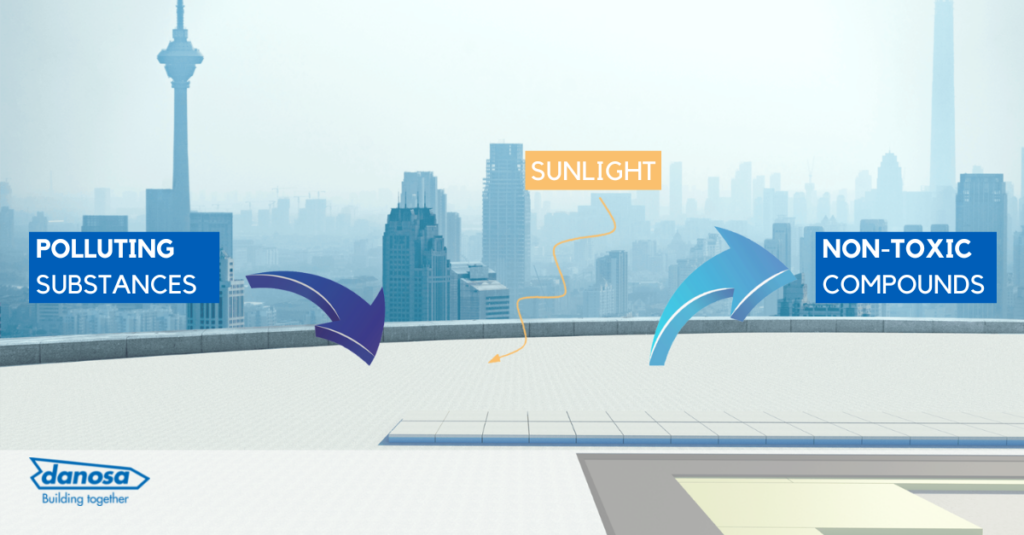

- Exceptional Durability: Hot liquid roofing is renowned for its resilience against harsh weather conditions, UV radiation, and environmental factors, ensuring a long-lasting roofing solution.

- Seamless Application: It seamlessly covers large or intricate roof surfaces, minimizing the risk of leaks and associated issues.

Cons:

- Complex Installation: The installation process for hot liquid roofing involves the use of heat or flame, which can pose risks if not executed properly and with adequate personal protective equipment (PPE).

- Limited Aesthetic Options: Hot liquid roofing offers a restricted range of finishes and colours, potentially limiting its suitability for certain projects.

Ultimately, the choice between cold and hot liquid roofing hinges on project specifics. Cold-applied liquid roofing is a practical choice for smaller, uncomplicated projects where quick installation is vital. On the other hand, hot melt structural waterproofing stands out for larger, more intricate projects that demand robust durability and weather resistance.

For expert guidance in selecting the ideal solution for your project, reach out to our team at DANOSA. Contact us at uksales@danosa.com or call +44 (0) 845 074 0553 to explore your options further.